Product Description

SPROCKET 5/8” X 3/8” 10B SERIES SPROCKETS

| For Chain Acc.to DIN8187 ISO/R 606 | |||||

| Tooth Radius r3 | 16.0mm | ||||

| Radius Width C | 1.6mm | ||||

| Tooth Width b1 | 9.0mm | ||||

| Tooth Width B1 | 9.1mm | ||||

| Tooth Width B2 | 25.5mm | ||||

| Tooth Width B3 | 42.1mm | ||||

| 10B SERIES ROLLER CHAINS | |||||

| Pitch | 15.875 mm | ||||

| Internal Width | 9.65 mm | ||||

| Roller Diameter | 10.16 mm | ||||

| Z | de | dp | SIMPLEX | DUPLEX | TRIPLEX | ||||||

| dm | D1 | A | dm | D2 | A | dm | D3 | A | |||

| 8 | 47.0 | 41.48 | 25 | 10 | 25 | 25 | 12 | 40 | 25 | 12 | 55 |

| 9 | 52.6 | 46.42 | 30 | 10 | 25 | 30 | 12 | 40 | 30 | 12 | 55 |

| 10 | 57.5 | 51.37 | 35 | 10 | 25 | 35 | 12 | 40 | 35 | 12 | 55 |

| 11 | 63.0 | 56.34 | 37 | 12 | 30 | 39 | 14 | 40 | 39 | 16 | 55 |

| 12 | 68.0 | 61.34 | 42 | 12 | 30 | 44 | 14 | 40 | 44 | 16 | 55 |

| 13 | 73.0 | 66.32 | 47 | 12 | 30 | 49 | 14 | 40 | 49 | 16 | 55 |

| 14 | 78.0 | 71.34 | 52 | 12 | 30 | 54 | 14 | 40 | 54 | 16 | 55 |

| 15 | 83.0 | 76.36 | 57 | 12 | 30 | 59 | 14 | 40 | 59 | 16 | 55 |

| 16 | 88.0 | 81.37 | 60 | 12 | 30 | 64 | 16 | 45 | 64 | 16 | 60 |

| 17 | 93.0 | 86.39 | 60 | 12 | 30 | 69 | 16 | 45 | 69 | 16 | 60 |

| 18 | 98.3 | 91.42 | 70 | 14 | 30 | 74 | 16 | 45 | 74 | 16 | 60 |

| 19 | 103.3 | 96.45 | 70 | 14 | 30 | 79 | 16 | 45 | 79 | 16 | 60 |

| 20 | 108.4 | 101.49 | 75 | 14 | 30 | 84 | 16 | 45 | 84 | 16 | 60 |

| 21 | 113.4 | 106.52 | 75 | 16 | 30 | 85 | 16 | 45 | 85 | 20 | 60 |

| 22 | 118.0 | 111.55 | 80 | 16 | 30 | 90 | 16 | 45 | 90 | 20 | 60 |

| 23 | 123.5 | 116.58 | 80 | 16 | 30 | 95 | 16 | 45 | 95 | 20 | 60 |

| 24 | 128.3 | 121.62 | 80 | 16 | 30 | 100 | 16 | 45 | 100 | 20 | 60 |

| 25 | 134.0 | 126.66 | 80 | 16 | 30 | 105 | 16 | 45 | 105 | 20 | 60 |

| 26 | 139.0 | 131.70 | 85 | 20 | 35 | 110 | 20 | 45 | 110 | 20 | 60 |

| 27 | 144.0 | 136.75 | 85 | 20 | 35 | 110 | 20 | 45 | 110 | 20 | 60 |

| 28 | 148.7 | 141.78 | 90 | 20 | 35 | 115 | 20 | 45 | 115 | 20 | 60 |

| 29 | 153.8 | 146.83 | 90 | 20 | 35 | 115 | 20 | 45 | 115 | 20 | 60 |

| 30 | 158.8 | 151.87 | 90 | 20 | 35 | 120 | 20 | 45 | 120 | 20 | 60 |

| 31 | 163.9 | 156.92 | 95 | 20 | 35 | 120 | 20 | 45 | 120 | 20 | 60 |

| 32 | 168.9 | 161.95 | 95 | 20 | 35 | 120 | 20 | 45 | 120 | 20 | 60 |

| 33 | 174.5 | 167.00 | 95 | 20 | 35 | 120 | 20 | 45 | 120 | 20 | 60 |

| 34 | 179.0 | 172.05 | 95 | 20 | 35 | 120 | 20 | 45 | 120 | 20 | 60 |

| 35 | 184.1 | 177.10 | 95 | 20 | 35 | 120 | 20 | 45 | 120 | 20 | 60 |

| 36 | 189.1 | 182.15 | 100 | 20 | 35 | 120 | 20 | 45 | 120 | 25 | 60 |

| 37 | 194.2 | 187.20 | 100 | 20 | 35 | 120 | 20 | 45 | 120 | 25 | 60 |

| 38 | 199.2 | 192.24 | 100 | 20 | 35 | 120 | 20 | 45 | 120 | 25 | 60 |

| 39 | 204.2 | 197.29 | 100 | 20 | 35 | 120 | 20 | 45 | 120 | 25 | 60 |

| 40 | 209.3 | 202.34 | 100 | 20 | 35 | 120 | 20 | 45 | 120 | 25 | 60 |

| 41 | 214.8 | 207.38 | *100 | 20 | 40 | 120 | 20 | 50 | *130 | 25 | 60 |

| 42 | 2,199 | 212.43 | *100 | 20 | 40 | 120 | 20 | 50 | *130 | 25 | 60 |

| 43 | 224.9 | 217.48 | *100 | 20 | 40 | 120 | 20 | 50 | *130 | 25 | 60 |

| 44 | 230.0 | 222.53 | *100 | 20 | 40 | 120 | 20 | 50 | *130 | 25 | 60 |

| 45 | 235.0 | 227.58 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 46 | 240.1 | 232.63 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 47 | 245.1 | 237.68 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 48 | 250.2 | 242.73 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 49 | 255.2 | 247.78 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 50 | 260.3 | 252.82 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 51 | 265.3 | 257.87 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 52 | 270.4 | 262.92 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 53 | 275.4 | 267.97 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 54 | 280.5 | 273.03 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 55 | 285.5 | 278.08 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 56 | 290.6 | 283.13 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 57 | 296.0 | 288.18 | *100 | 20 | 40 | *120 | 20 | 50 | *130 | 25 | 60 |

| 58 | 300.7 | 293.23 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 64 |

| 59 | 305.7 | 298.28 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 64 |

| 60 | 310.8 | 303.33 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 64 |

| 62 | 321.4 | 313.43 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 64 |

| 64 | 331.5 | 323.53 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 65 | 336.5 | 328.58 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 66 | 341.6 | 333.64 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 68 | 351.7 | 343.74 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 70 | 361.8 | 353.84 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 72 | 371.9 | 363.94 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 75 | 387.1 | 379.10 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 76 | 392.1 | 384.15 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 78 | 402.2 | 394.25 | *100 | 20 | 43 | *120 | 20 | 57 | *130 | 25 | 67 |

| 80 | 412.3 | 404.36 | *100 | 20 | 43 | *130 | 20 | 57 | *130 | 25 | 67 |

| 85 | 437.6 | 429.62 | *100 | 20 | 50 | *130 | 20 | 58 | *130 | 25 | 67 |

| 90 | 462.8 | 454.88 | *100 | 20 | 50 | *130 | 20 | 58 | *130 | 25 | 67 |

| 95 | 488.5 | 480.14 | *100 | 20 | 50 | *130 | 20 | 58 | *130 | 25 | 67 |

| 100 | 513.4 | 505.40 | *100 | 20 | 50 | *130 | 20 | 58 | *130 | 25 | 67 |

| 110 | 563.9 | 555.92 | *100 | 20 | 50 | *130 | 20 | 58 | *130 | 25 | 67 |

| 114 | 584.1 | 576.13 | *100 | 20 | 50 | *130 | 20 | 58 | *130 | 25 | 67 |

| 120 | 614.4 | 606.45 | *100 | 20 | 50 | *130 | 20 | 58 | *130 | 25 | 67 |

| 125 | 639.7 | 631.51 | *100 | 20 | 50 | *130 | 20 | 58 | *130 | 25 | 67 |

Notice: *welding hub

BASIC INFO.

| Product name | DIN ISO Standard Sprocket for Roller Chain |

| Materials Available | 1. Stainless Steel: SS304, SS316, etc |

| 2. Alloy Steel: C45, 45Mn, 42CrMo, 20CrMo, etc | |

| 3. OEM according to your request | |

| Surface Treatment | Heat treatment, Quenching treatment, High frequency normalizing treatment, Polishing, Electrophoresis paint processing, Anodic oxidation treatment, etc |

| Characteristic | Fire Resistant, Oil Resistant, Heat Resistant, CZPT resistance, Oxidative resistance, Corrosion resistance, etc |

| Design criterion | ISO DIN ANSI & Customer Drawings |

| Size | Customer Drawings & ISO standard |

| Application | Industrial transmission equipment |

| Package | Wooden Case / Container and pallet, or made-to-order |

| Certificate | ISO9001: 2008 |

| Advantage | Quality first, Service first, Competitive price, Fast delivery |

| Delivery Time | 20 days for samples. 45 days for official order. |

INSTALLATION AND USING

The chain spoket, as a drive or deflection for chains, has pockets to hold the chain links with a D-profile cross section with flat side surfaces parallel to the centre plane of the chain links, and outer surfaces at right angles to the chain link centre plane. The chain links are pressed firmly against the outer surfaces and each of the side surfaces by the angled laying surfaces at the base of the pockets, and also the support surfaces of the wheel body together with the end sides of the webs formed by the leading and trailing walls of the pocket.

NOTICE

When fitting new chainwheels it is very important that a new chain is fitted at the same time, and vice versa. Using an old chain with new sprockets, or a new chain with old sprockets will cause rapid wear.

It is important if you are installing the chainwheels yourself to have the factory service manual specific to your model. Our chainwheels are made to be a direct replacement for your OEM chainwheels and as such, the installation should be performed according to your models service manual.

During use a chain will stretch (i.e. the pins will wear causing extension of the chain). Using a chain which has been stretched more than the above maximum allowance causes the chain to ride up the teeth of the sprocket. This causes damage to the tips of the chainwheels teeth, as the force transmitted by the chain is transmitted entirely through the top of the tooth, rather than the whole tooth. This results in severe wearing of the chainwheel.

FOR CHAIN STHangZhouRDS

Standards organizations (such as ANSI and ISO) maintain standards for design, dimensions, and interchangeability of transmission chains. For example, the following Table shows data from ANSI standard B29.1-2011 (Precision Power Transmission Roller Chains, Attachments, and Sprockets) developed by the American Society of Mechanical Engineers (ASME). See the references[8][9][10] for additional information.

ASME/ANSI B29.1-2011 Roller Chain Standard SizesSizePitchMaximum Roller DiameterMinimum Ultimate Tensile StrengthMeasuring Load25

| ASME/ANSI B29.1-2011 Roller Chain Standard Sizes | ||||

| Size | Pitch | Maximum Roller Diameter | Minimum Ultimate Tensile Strength | Measuring Load |

|---|---|---|---|---|

| 25 | 0.250 in (6.35 mm) | 0.130 in (3.30 mm) | 780 lb (350 kg) | 18 lb (8.2 kg) |

| 35 | 0.375 in (9.53 mm) | 0.200 in (5.08 mm) | 1,760 lb (800 kg) | 18 lb (8.2 kg) |

| 41 | 0.500 in (12.70 mm) | 0.306 in (7.77 mm) | 1,500 lb (680 kg) | 18 lb (8.2 kg) |

| 40 | 0.500 in (12.70 mm) | 0.312 in (7.92 mm) | 3,125 lb (1,417 kg) | 31 lb (14 kg) |

| 50 | 0.625 in (15.88 mm) | 0.400 in (10.16 mm) | 4,880 lb (2,210 kg) | 49 lb (22 kg) |

| 60 | 0.750 in (19.05 mm) | 0.469 in (11.91 mm) | 7,030 lb (3,190 kg) | 70 lb (32 kg) |

| 80 | 1.000 in (25.40 mm) | 0.625 in (15.88 mm) | 12,500 lb (5,700 kg) | 125 lb (57 kg) |

| 100 | 1.250 in (31.75 mm) | 0.750 in (19.05 mm) | 19,531 lb (8,859 kg) | 195 lb (88 kg) |

| 120 | 1.500 in (38.10 mm) | 0.875 in (22.23 mm) | 28,125 lb (12,757 kg) | 281 lb (127 kg) |

| 140 | 1.750 in (44.45 mm) | 1.000 in (25.40 mm) | 38,280 lb (17,360 kg) | 383 lb (174 kg) |

| 160 | 2.000 in (50.80 mm) | 1.125 in (28.58 mm) | 50,000 lb (23,000 kg) | 500 lb (230 kg) |

| 180 | 2.250 in (57.15 mm) | 1.460 in (37.08 mm) | 63,280 lb (28,700 kg) | 633 lb (287 kg) |

| 200 | 2.500 in (63.50 mm) | 1.562 in (39.67 mm) | 78,175 lb (35,460 kg) | 781 lb (354 kg) |

| 240 | 3.000 in (76.20 mm) | 1.875 in (47.63 mm) | 112,500 lb (51,000 kg) | 1,000 lb (450 kg |

For mnemonic purposes, below is another presentation of key dimensions from the same standard, expressed in fractions of an inch (which was part of the thinking behind the choice of preferred numbers in the ANSI standard):

| Pitch (inches) | Pitch expressed in eighths |

ANSI standard chain number |

Width (inches) |

|---|---|---|---|

| 1⁄4 | 2⁄8 | 25 | 1⁄8 |

| 3⁄8 | 3⁄8 | 35 | 3⁄16 |

| 1⁄2 | 4⁄8 | 41 | 1⁄4 |

| 1⁄2 | 4⁄8 | 40 | 5⁄16 |

| 5⁄8 | 5⁄8 | 50 | 3⁄8 |

| 3⁄4 | 6⁄8 | 60 | 1⁄2 |

| 1 | 8⁄8 | 80 | 5⁄8 |

Notes:

1. The pitch is the distance between roller centers. The width is the distance between the link plates (i.e. slightly more than the roller width to allow for clearance).

2. The right-hand digit of the standard denotes 0 = normal chain, 1 = lightweight chain, 5 = rollerless bushing chain.

3. The left-hand digit denotes the number of eighths of an inch that make up the pitch.

4. An “H” following the standard number denotes heavyweight chain. A hyphenated number following the standard number denotes double-strand (2), triple-strand (3), and so on. Thus 60H-3 denotes number 60 heavyweight triple-strand chain.

A typical bicycle chain (for derailleur gears) uses narrow 1⁄2-inch-pitch chain. The width of the chain is variable, and does not affect the load capacity. The more sprockets at the rear wheel (historically 3-6, nowadays 7-12 sprockets), the narrower the chain. Chains are sold according to the number of speeds they are designed to work with, for example, “10 speed chain”. Hub gear or single speed bicycles use 1/2″ x 1/8″ chains, where 1/8″ refers to the maximum thickness of a sprocket that can be used with the chain.

Typically chains with parallel shaped links have an even number of links, with each narrow link followed by a broad one. Chains built up with a uniform type of link, narrow at 1 and broad at the other end, can be made with an odd number of links, which can be an advantage to adapt to a special chainwheel-distance; on the other side such a chain tends to be not so strong.

Roller chains made using ISO standard are sometimes called as isochains.

WHY CHOOSE US

1. Reliable Quality Assurance System

2. Cutting-Edge Computer-Controlled CNC Machines

3. Bespoke Solutions from Highly Experienced Specialists

4. Customization and OEM Available for Specific Application

5. Extensive Inventory of Spare Parts and Accessories

6. Well-Developed CZPT Marketing Network

7. Efficient After-Sale Service System

The 219 sets of advanced automatic production equipment provide guarantees for high product quality. The 167 engineers and technicians with senior professional titles can design and develop products to meet the exact demands of customers, and OEM customizations are also available with us. Our sound global service network can provide customers with timely after-sales technical services.

We are not just a manufacturer and supplier, but also an industry consultant. We work pro-actively with you to offer expert advice and product recommendations in order to end up with a most cost effective product available for your specific application. The clients we serve CZPT range from end users to distributors and OEMs. Our OEM replacements can be substituted wherever necessary and suitable for both repair and new assemblies.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard, Nonstandard |

|---|---|

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

| Hardness: | Hardened Tooth Surface |

| Manufacturing Method: | Rolling Gear, Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | 1045, Stainless Steel |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Compatibility of Chain Sprockets with Wheels

In general, chain sprockets are designed to work with specific types of wheels, and there are certain requirements for ensuring proper compatibility:

- Chain Size and Pitch: The chain sprocket must match the size and pitch of the chain it is intended to work with. For example, if you have a roller chain with a pitch of 0.625 inches, you need a sprocket with the same pitch to ensure a proper fit.

- Number of Teeth: The number of teeth on the sprocket should be compatible with the number of chain links. The chain should mesh smoothly with the sprocket without any binding or skipping.

- Tooth Profile: The tooth profile of the sprocket should match the shape of the chain’s rollers to ensure smooth engagement and minimize wear.

- Shaft Size: The center hole (bore) of the sprocket should match the diameter of the shaft it will be mounted on. Using the correct shaft size ensures a secure fit and prevents wobbling.

- Hub Configuration: Some sprockets have hubs, which are extensions on either side of the sprocket. The hub’s length and configuration should match the requirements of the specific application.

- Material and Strength: Consider the material and strength of the sprocket based on the application’s load and environmental conditions. Heavy-duty applications may require sprockets made of robust materials to withstand the forces and stresses.

It’s crucial to follow the manufacturer’s specifications and guidelines when selecting a chain sprocket for a particular wheel. Mixing incompatible sprockets and wheels can result in premature wear, inefficiencies, and potential safety hazards. If you are unsure about the compatibility, consult with the manufacturer or a knowledgeable expert to ensure you choose the right sprocket for your specific application.

Using wheel sprocket Assembly in Robotics and Automation

Yes, wheel sprocket assemblies are commonly used in robotics and automation systems to transmit power and facilitate movement. These systems offer several advantages for robotic applications:

- Efficiency: wheel sprocket assemblies provide efficient power transmission, ensuring smooth and precise movement of robotic components.

- Compact Design: The compact nature of sprockets and wheels allows for space-saving designs, making them ideal for robotic applications where space is limited.

- Precision: Sprockets and wheels with accurate teeth profiles provide precise motion control, crucial for robotics and automation tasks that require high levels of accuracy.

- Low Noise: Properly lubricated and maintained wheel sprocket systems generate minimal noise during operation, contributing to quieter robotic movements.

- Customizability: wheel sprocket assemblies can be customized to suit specific robotic requirements, such as different gear ratios, sizes, and materials.

- Multiple Configurations: Depending on the robotic application, different configurations like single or multiple sprockets, idler sprockets, or rack and pinion systems can be used.

- High Load Capacity: Sprockets made from durable materials like steel can handle substantial loads, making them suitable for heavy-duty robotic tasks.

Examples of robotics and automation systems that commonly use wheel sprocket assemblies include:

- Robotic Arms: wheel sprocket systems are utilized in robotic arms to control their movement and reach.

- Automated Guided Vehicles (AGVs): AGVs use wheel sprocket assemblies for propulsion and steering, enabling them to navigate autonomously.

- Conveyor Systems: In automated factories, conveyor belts are often driven by sprockets and wheels for efficient material handling.

- Mobile Robots: Wheeled mobile robots use wheel sprocket assemblies to drive their wheels, enabling them to move in various directions.

- Robot Grippers: wheel sprocket mechanisms can be integrated into robot grippers to facilitate gripping and handling objects.

The choice to use wheel sprocket assemblies in robotics and automation depends on the specific application requirements, load capacity, precision, and environmental conditions. By selecting the appropriate sprockets, wheels, and materials, engineers can ensure reliable and efficient robotic performance in a wide range of automated tasks.

Calculating Gear Ratio for a wheel sprocket Setup

In a wheel sprocket system, the gear ratio represents the relationship between the number of teeth on the sprocket and the number of teeth on the wheel. The gear ratio determines the speed and torque relationship between the two components. To calculate the gear ratio, use the following formula:

Gear Ratio = Number of Teeth on Sprocket ÷ Number of Teeth on Wheel

For example, if the sprocket has 20 teeth and the wheel has 60 teeth, the gear ratio would be:

Gear Ratio = 20 ÷ 60 = 1/3

The gear ratio can also be expressed as a decimal or percentage. In the above example, the gear ratio can be expressed as 0.3333 or 33.33%.

It’s important to note that the gear ratio affects the rotational speed and torque of the wheel sprocket. A gear ratio greater than 1 indicates that the sprocket’s speed is higher than the wheel’s speed, resulting in increased rotational speed and reduced torque at the wheel. Conversely, a gear ratio less than 1 indicates that the sprocket’s speed is lower than the wheel’s speed, resulting in decreased rotational speed and increased torque at the wheel.

The gear ratio is crucial in various applications where precise control of speed and torque is required, such as bicycles, automobiles, and industrial machinery.

editor by CX 2024-02-11

China manufacturer & factory supplier for HangZhou in Guwahati India EPG Chinese supplier 8000 series cycloidal pin wheel gear reducer drives gearbox With high quality best price & service

EPG significant company and supplier of ball bearings and energy transmission tools. Since it’s commencing in 1992, EPG has developed into 1 of the leading suppliers in the market. Important factors that have contributed to our development is our commitment to the fundamentals of progressive style, aggressive pricing, extraordinary buyer provider, and solution availability.If you are interested in any of our items or would like to discuss a likely order, you should feel cost-free to get in touch with us.

Overview

Adhering to “Survival by Top quality, Development by Technological innovation & Credit history”, The firm will continuously boost product overall performance to meet the increasing buyer needs in the demanding type of operate.

Quick Specifics

- Relevant Industries:

-

Manufacturing PlanSlip clutch type on the rotary tiller, yet again slight oozing of grease on the UJ, do not grease the clutch these run dry and need to be “slipped” at the very least after a year to avoid rusting togethert

- Gearing Arrangement:

-

Helical

- Model Amount:

-

8000 collection cycloid pin-wheel gearbox

- Rated Electricity:

-

.09-75Kw

- Name:

-

Shanghai Goldgun Chinese provider 8000 collection cycloidal pin wheel gear

- Coloration:

-

blue,green

- Mainland:

-

China

- Materials:

-

We distribute several other items that are not shown over, but are nonetheless easily offered. Come to feel cost-free to give us a phone or send us an electronic mail. We are often all set to help.

solid iron

- MOQ:

-

20pc

- Series:

-

cycloidal cycloidal gearbox

- Electricity Selection:

-

.09-75Kw

- Installation Kind:

-

foot-mounted horizontal and flange vertical

Supply Capacity

- Provide Capability:

- 6000 Piece/Pieces for every Thirty day period Shanghai Goldgun Chinese supplier 8000 series cycloidal pin whee

Packaging & Supply

- Packaging Particulars

- picket scenario for Shanghai Goldgun Chinese supplier 8000 sequence cycloidal pin wheel gear reducer drives gearbox

- Port

- Shanghai , Ningbo , Shenzhen , Tianjin ect

On the web Customization

| Gearing Arrangement | Cycloidal |

| Output Torque | single-phase:16.9-28500Nm two-phase:206-60800Nm |

| Enter Velocity | ≤2000rpm |

| Output Pace | .6-375rpm |

| Place of Origin | China |

| Manufacturer Identify | 202001EPG |

| China | Zhejiang |

| Product Quantity | 8000 sequence cycloid pin-wheel gearbox |

| Rated Energy | .09-75Kw |

| Title | Shanghai Goldgun Chinese supplier 8000 series cycloidal pin wheel gear |

| Colour | blue,eco-friendly |

| Mainland | China |

| Content | solid iron |

| MOQ | 20pc |

| Sequence | cycloidal cycloidal gearbox |

| Energy Assortment | .09-75Kw |

| Installation Kind | foot-mounted horizontal and flange vertical |

EK series helical- …

Gearbox for Snow T …

CHO TKM/TKB BEVEL …

consumer-described

A: Your inquiry related to our goods or charges will be replied in 24 several hours.

B: Defense of your income spot, concepts of design and all your personal details.

C: Ideal quality and competitive price tag.

……

1) How can I area get?

A: You can speak to us by e-mail about your buy details, or place purchase on line.

2) How can I spend you?

A: After you validate our PI, we will ask for you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are making use of.

……

Best China manufacturer & factory china in Dublin Ireland supplier P series high quality small electric motor planetary gear transmission gearbox With high quality best price

Our AdvantagesProducts Big volume in Stock, No MOQ required We comply with all the international standards, such as ISO9001 and TS16949 standards.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Model Number:

-

P3NA P2NA P3SA 10 11 12 13 14

How Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment.

- Rated Power:

-

1.5~6229KW(customized)

- Pole:

-

one two three stage

- Ratio:

-

2.8-2000

- Housing Material:

-

Cast Iron

- Material:

-

20CrMn

- Working temperature:

-

-40~45℃

- Type:

-

P Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.series small electric motor planetary gear transmission gearbox

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

92%~96%

Supply Ability

- Supply Ability:

- 5000 Set/Sets per Year P small electric motor planetary gear transmission gearbox

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for P series high quality small electric motor planetary gear transmission gearbox

- Port

- Qingdao

Online Customization

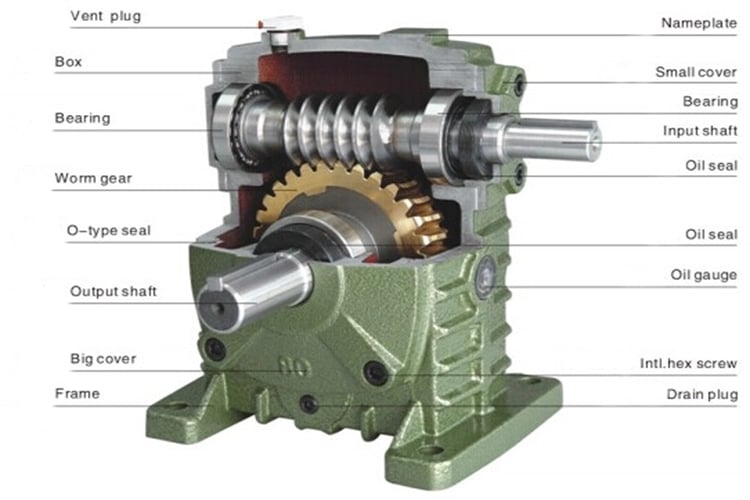

Machining of the gearbox To make a worm gearbox, first take a blank of an alloy. A bronze bearing is made in the center of the blank. The hobbing cutter is then used to reduce the diameter of the blank relative to the finished height of the tooth tip on the gear wheel, so the depth of the cut needs to be added to the blank’s diameter. The necessary threading tool is grind to cut the worm. The side clearance on the left-hand side of the cutter tip is allowed for the worm’s pitch angle. The best finish is put on the cutting tool using a slip stone. Gear blank is then mounted on a turntable that acts as a bearing support. This bearing support is mounted on the rear of the lathe cross-slide with the hobbing cutter mounted between the centers. The two worms are then machined, out of which one is made the cutter and finally the cutter is used to machine the worm gear.

Product Description

YOUR PROFESSIONAL MANUFACTURE

—— SINCE 1995

NGW / P Series Planetary Gear Reducer

Sun Gear, Planetary Gear,Internal GearRing,Staging Gear

Chinese Speed Reducer widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

NGW Series Mini Planetary Gearbox for concrete mixer including one-stage,two-stage and three-stage, it is suitable for the required speed ratio≤1500r/min, working temperature around -40~45℃, two runs alternative in direction.

P series Mini Planetary Gearbox for concrete mixer including two-stage and three-stage, it is suitable for the required speed ratio 25-4000, the ratio will be larger in combination with R,K series reducer.

Feature:

-

Modular design,right angle planetary gear box for slewing

-

Material: Cast iron HT 250 for housing; 20CrMnTi for Gear and Shaft

-

Sun gear, Planetary gear and Ring gear all c which will improve the efficiency and service life of the reducer.

-

Input mode: coaxial input, helical gear input, bevel-helical gear input

-

Output mode: internal involute spline, hollow shaft with shrink disk, external involute spline, solid shaft with flat key.

-

Mounting mode: Horizontal,Vertical,Torque-arm.planetary motor gearbox for concrete mixer

Specification

P series high quality electric motor planetary gear transmission gearbox

Mounting Diamensions: (please contact us for more types & model)

| Type | Planetary gear units |

| Size | 9-34 |

| Stage | 2 stage 3 stage |

| Ratio | 25-4000 |

| Input mode | coaxial input, helical gear input, bevel helical gear input |

| Output mode | A hollow shaft with shrink disk B solid shaft with parallel key C hollow shaft with involute splines D solid shaft with involute splines |

| Mouting mode | horizontal, vertical, torque arm |

Model selection of right angle planetary gear box for slewing:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.planetary motor gearbox for concrete mixer.right angle planetary geared motor for slewing drive.China right angle planetary geared motor speed reducer gearbox for slewing drive.

Technology

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. Mini Planetary Gearbox for concrete mixer. right angle planetary gear box for slewing.planetary motor gearbox for concrete mixer.right angle planetary geared motor for slewing drive.China right angle planetary geared motor speed reducer gearbox for slewing drive.

Packaging & Shipping

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

Best China manufacturer & factory china supplier NGW type 3 stage ball mill gearbox planetary reducer gear box for concrete mixer 10 liters With high quality best price

We are looking forward to developing successful business relationships with new clients around the world in the future.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

single two three stage

- Ratio:

-

2.8-2000

- Application:

-

for wind turbine generator ball mill

- Material:

-

20CrMnTi Cast Iron or steel

- Working temperature:

-

-40~45℃

- Type:

-

gearbox planetary reducer gear box for concrete mixer 10 liters

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

92%~96%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

Packaging & DeliverySlip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design.

-

Lead Time

: -

Quantity(Bags) 1 – 1 >1 Est. Time(days) 15 To be negotiated

Online Customization

The company was certified by ISO9001:2008 Quality Management System.

Product Description

YOUR PROFESSIONAL MANUFACTURE

—— SINCE 1995

NGW / P Series Planetary Gear Reducer

Sun Gear, Planetary Gear, Internal GearRing, Staging Gear

China supplier planetary gear reducer for marine

Chinese Speed Reducer widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

NGW Series planetary reducer gear box including one-stage,two-stage and three-stage, it is suitable for the required speed ratio≤1500r/min, working temperature around -40~45℃, two runs alternative in direction.

P series including tow-stage and three-stage, it is suitable for the required speed ratio 25-4000, the ratio will be larger in combination with R,K series reducer.

Feature:

-

Modular design

-

Material: Cast iron HT 250 for housing; 20CrMnTi for Gear and Shaft

-

Sun gear, Planetary gear and Ring gear all c which will improve the efficiency and service life of the reducer.

-

Input mode: coaxial input, helical gear input, bevel-helical gear input

-

Output mode: internal involute spline, hollow shaft with shrink disk, external involute spline, solid shaft with flat key.

-

Mounting mode: Horizontal,Vertical,Torque-arm.planetary reducer for concrete mixer plant

Specification

Mounting Diamensions mini 2 speed planetary gearbox with reverse for concrete mixer:

(please contact us for more types & model)

| NGW Series Specification | |||||||||||||||

| Size | NGW 42 | NGW 52 | NGW 62 | NGW 72 | NGW 82 | NGW 92 | NGW 102 | NGW 112 | NGW 122 | NGW 73 | NGW 83 | NGW 93 | NGW 103 | NGW 113 | NGW 123 |

| Input Speed rpm |

600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 |

| Input power rating(kw) |

42.5-30.2 | 3.6-44.2 | 4.7-66.3 | 7-94.3 | 10-128 | 13.2-185 | 19.4-257 | 28.3-364 | 38.6-517 | 0.1-2.7 | 0.13-4.6 | 0.17-8.3 | 0.27-9.2 | 0.39-16.5 | 0.57-20.4 |

| Ratio | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 7-22 | 7-22 | 7-22 | 7-22 | 7-22 | 7-22 |

| Permissible torque N.m |

2320-2980 | 3320-4350 | 4350-6060 | 6060-8460 | 9310-11630 | 12980-16670 | 18470-23670 | 26200-34600 | 35700-47790 | 2670-8550 | 3730-11850 | 5010-17010 | 7410-24160 | 10580-35360 | 15860-49060 |

Model selection for planetary gearbox for concrete mixer:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power ofThe computer then compares the output subassembly stack height to the distance between the housing bearing seats and calculates the shim pack required for the desired bearing endplay. Using the worm-gear centerline measurement, it shows assemblers how to distribute shims between the front and rear bearings to precisely center the gear in the housing. Measurement accuracy is ±0.001 in. Total cycle time, excluding loading and unloading, is less than 20 sec. the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. China supplier planetary gear reducer for marine. NGW type 3 stage ball mill gearbox planetary reducer gear box for concrete mixer 10 liters.

Technology

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. China supplier planetary gear reducer for marine.planetary reducer for concrete mixer plant. NGW type 3 stage ball mill gearbox planetary reducer gear box for concrete mixer 10 liters.

Our Services

Packaging & Shipping

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

Best China manufacturer & factory Gear reducer best quality gearbox ZSY series with oil With high quality best price

Great attention has been paid on environmental protection and energy saving.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Model Number:

-

ZSY

- Product name:

-

ZSY gear box

- Product Keywords:

-

gearbox for metal flattening machine

- Color:

-

Green

- ZSY Reducer gearbox:

-

ZSY Reducer

- gearbox:

-

Reducer gearbox

- gearbox for material:

-

gearbox for dryer

- Gear speed reducer:

-

ZSY gear speed reducer

- Material:

-

45C Steel

Supply Ability

- Supply Ability:

- 500 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- wooden box

- Port

- Shang Hai

Online Customization

Product Description

ZSY Cylindrical gear reducer gear carburizing, quenching, grinding, high bearing capacity, low noise; mainly used for belt conveyor and various kinds of transport machinery, can also be used to drive other general machinery. It has the advantages of high bearing capability, long service life, small volume, high efficiency, light weight, for the input shaft and the output shaft is vertically arranged in the driving device.

The field of cylindrical gear reducer is widely used in metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment etc..

ZSY Cylindrical gear speed reducer

ZSY Cylindrical gear speed reducer is a three-level transmission of involute cylindrical gear reducer, mainly used inmining, metallurgy, cement, construction, chemical industry, light industry, etc all kinds of mechanical equipment, reduction drive, is suitable for the workplace being limited by the structure adopts the vertical installation, high-speed spindle speed not more than 1500 r/min, the work environment to + 40 °C and 40 °C -, can positive &negative operation.

Main Features

1.gear with high strength and low carbon alloy steel by carburizing quenching, tooth surface hardness of HRC58-62, gear are CNC grinding process, high precision, good contact.

2.transmission rate is high: single stage is greater than 96.5%, double stage is greater than 93%, grade three is greater than 90%.

3.stable operation, low noise.

4.small size, light weight, long service life, high carrying capacity.

5.easy to be disassembled and easy to install.

Our Company

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for ….

Application area

Certifications

Sales territory

Packing & Delivery

|

PackagingThe company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc. |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZheJiang China.welcome to our factory to have a visit.

Q2: How we select models aCommercial policy Our commercial policy is based on the service. And we understand by service the delivery of the product in the down times that our costumers demand us. We have developed a logistic system in our company that allows us to send products the same day of its order whenever it is made this order before 18:00 hours, to this service we have called it “EPG Express”.nd specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gSFI M100 PTO AdapterAs a precautionary measure, it is a good idea to purchase a PTO adapter to ensure compatibility with your particular tractor model.earboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Contact us

Mobile: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Add:No.789 ShenHua Road, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd.

Best China manufacturer & factory VF series worm speed reducer gearbox VF30 worm gear motor for step motor servo motor With high quality best price

Additionally, all our production procedures are in compliance with ISO9002 standards for a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- ITEM NO:

-

SYF

- Housing Material:

-

Aluminum Steel

- Certificate:

-

ISO9001

- Ratio:

-

5~300

- Bearing:

-

NSK Bearing

- Gear material:

-

45# Cast Steel

- Warranty:

-

1-2 Years

- Mounting Position:

-

Flange Mounted

- Output torque:

-

2.6-1195N.M

- Intput speed:

-

750~3000rpm

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 5 6 – 10 >10 Est. Time(days) 3 7 To be negotiated Maintenance This kind of gear reducer is provided with a permanent lubrication, so it does not need any kind of maintenance.

Online Customization

Product Description

VF SERIES WORM GEAR SPEED REDUCER

VF series worm gear reducer motor is designed with the most advanced materials and manufacturing technology, with compact structure, reliable quality, a variety of optional installation position and can be with torque limiter and other characteristics, helical gear – worm gear and double worm gear reducer can be provided in combination.

|

Structural Features: |

||||||||

|

1. |

Single stage worm drive, compact structure |

|||||||

|

2. |

High quality aluminum alloy die casting box body, lightweight |

|||||||

|

3. |

Good heat exchange performance, fast heat dissipation |

|||||||

|

4. |

Easy installation, flexible and light |

|||||||

|

5. |

Low noise, durable |

|||||||

Are you searching for a PTO water pump or PTO- driven generator? Hundreds of PTO parts from EPG mean you can find PTO shaft parts and accessories for whatever kind of equipment you’re working with. From PTO drive shafts to shield parts, we have dozens of replacement PTO parts. We stock Eurocardan parts as well as Neapco parts because those are names you can trust. Whether you need flex couplers or PTO shaft assemblies, we can help.

PRECISION GEAR

20CrMn Ti material – low carbon alloy steel

Imported gear grinding machine processing, high hardness, stable performance.

Vacuum furnace carburizing heat treatment, carburizing layer uniform.

HIGH QUALITY SHELL MATERIAL

The box body is made of HT200 material,which is cleaned by professional screening and washing equipment to ensure that the inner cavity of the box body is cleaner without iron filings.

HIGH QUALITY OUTPUT SHAFT

New standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer

VF SERIEPG is willing to cooperate sincerely and develop commonly with friends!ES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Our Company

HANGZHOU EVER-POWER GROUP, ONE OF THE BIGGEST GEARBOX FACTORY IN CHINA, ELECTROMECHANICAL EQUIPMENT SUPPLY STATION

Our company is located in the city of HangZhou, ZheJiang Province of China.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area

worm gear speed reducer.

It is widely used in many fields such as metallurgy, mine, printing, chemical industry, textile, foodstuff, medicine, rubber and plastic,etc.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Q1: Are you a trading company or a manufacturer ?

A: We are a manufacturer in ZheJiang Province, China. Our company owns the ability of manufacturing, processing,designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A4: We will reply the enquiries without any delay, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Professional price China Transmission Products Chinese Gearbox S Series Special Standard High Preciosion Spur Gear

Detail Information

Gearbox–S37-97 Dimensions

Gearbox Specifications

| Size |

Shaft Solid Dia. (mm) |

Hollow Shaft Dia. (mm) |

Center Height (mm) |

Output Flange Dia. (mm) |

Power (kw) |

Ratio |

Permissible Torque (N. M) |

Weight (KGS) |

| 37 | φ20k6 | φ20h7 | 82 | φ120/160 | 0.18-0.75 | 10.27-165.71 | 90 | 7 |

| 47 | φ25k6 | φ25h7 | 100 | φ160 | 0.18-1.50 | 11.46-2With EPG brand registered in more than 70 countries like America , Europe , Japan and so on, it has partners among world top enterprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, etc.44.74 | 170 | 10 |

| 57 | φ30k6 | φ30h7/35h7 | 180 | φ200 | 0.18-3.0 | 10.78-196.21 | 300 | 14 |

| 67 | φ35k6 | φ40h7/45h7 | 140 | φ200 | 0.25-5.50 | 11.55-227.20 | 520 | 26 |

| 77 | φ45k6 | φ50h7/60h7 | 180 | φ250 | 0.55-7.50 | 9.96-241.09 | 1270 | 50 |

| 87 | φ60k6 | φ60h7/70h7 | 225 | φ350 | 0.75-15.0 | 11.83-223.26 | 2280 | 100 |

| 97 | φ70k6 | φ70h7/90h7 | 280 | φ450 | 1.50-22.0 | 12.5-230.48 | 4000 | 170 |

Product Information

Availability:

* Standard gearbox

High Performance:

√ Strong ultimate tensile strength

√ Perfect surface treatment

√ Durable,Flexible

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

High quality:

√Corrosion resistance

√Durable, Robust and Reliable

√Bad condition resistance

√Lower weight–high speed

Application industries:

√Harbor and shipping

√Hoist and transport

√Electric power

√Coal mining

√Cement and construction

……

Package:

Plastic bag+Neutral box +Plywood box

Advantages:

*High modular design

*High loading support, stable tranroller chains. Conveyor chains, engineered chains, silent chains, and tabletop chains are also available. Other power transmission products include pillow blocks, conveyor idlers, conveyor pulleys, drive shafts, gear racks, gear reducers, gears, overrunning clutches, motor bases, pulleys, screw conveyors, shaft couplings, sheaves, speed reducers, sprockets, tapered bushings, tensioners, torque limiters, and universal joints. Services such as bearing reconditioning and repair, ball screw repair, custom contract machining, gearbox repair and overrunning clutch repair services are available. Roller chains can be used in conveyor and machinery manufacturing, industrial processing, machine rebuilding, waste water, sand and gravel, tool and die, steel, metals and scrap processing industrial applications.smitting and low noise level.

*Excellent sealing, wide range of industry application.

*High efficiency and save power.

*Save cost and low maintenance.

EPT ansi transmission chains and sprockets are widely used in Agriculture,Printing,Chemical,Food and Beverage,General Machinery,Oil and Gas,Packaging and Logistics,Paper Industry,Textile industry,Woodeworking Machinery and so on.

The biggest characteristic is that the chains can be customized in different standard and materials according to your requirements. Made from the steel and the up-to-date skills as well as precision procedures, the high quality roller chain can withstand strong pressure and high temperature.

| Special Standard High Preciosion Spur Gear |